My 1985 VW vanagon was running for about fifteen minutes and then losing power. It would idle but did not have enough power to move. This loss of power would occur about fifteen minutes into my test drives and would begin as hesitation and what seemed like missing. Once the symptoms set in, I opened the engine cover and wiggled the spark plug wires and coil. When I just touched the wires coming out of the distributor (the hall sender wires) it died immediately. I started it back up, again touched the wires and it immediately died. This seemed like a pretty good indication that I had a problem with the ignition wires. I ordered a new ignition harnes from Kyle at kyleautomotice specialists and a couple days later a beautiful new harness with new plugs and perfect wires arrived in the mail. After putting in a new ignition wire harness into the 1.9 waterboxer (as well as a new coil and new spark plug wire set which I may or may not have needed), I went off for a test drive. It was obviously missing. I pulled the plugs and number three was wet. I pulled the spark plug wire off number three while running and no difference. I checked number three for spark by cranking the engine with the plug pulled and a spark plug put into the wire and held near the engine block to ground (rather than through your body) and confirmed spark. I pulled the fuel injector and cranked the engine to confirm a pulsing cone shaped spray and no dripping after turned off. All those checked out so I checked compression in #3 and found 0 compression. I pulled the valve cover off and found a broken compression spring. This was a problem and hopefully my only current problem.

I have a couple of spare heads complete with valves and springs from the engine that broke a connecting rod, but I did not know how to remove the valves and the springs. After reviewing the Samba forum and receiving some response to a post, I had enough to tackle the project. The samba is an amazing source of VW information, technical guidance, moral support and inspiration.

Working with engines and particular older engines sometimes requires the exact tool. A great deal of the work on the 1.9 and 2.1 waterboxers can be accomplished with a 13mm socket but there are somethings that you just cannot do easily without the right tool. A valve spring compressor is essential to free up the keepers that hold the valve in place. It is available at a FLAPS (friendly local auto parts store) and is shown above.

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs  through the springs, is capped with a holder/washer and the holder/washer is held on with a keeper. The keeper is actually two wedge shaped semi circles that catch the ringed grooves in the stem and then jam in the holder/washer. At right is a picture of the parts of the valve and spring assembly.

through the springs, is capped with a holder/washer and the holder/washer is held on with a keeper. The keeper is actually two wedge shaped semi circles that catch the ringed grooves in the stem and then jam in the holder/washer. At right is a picture of the parts of the valve and spring assembly.

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs  through the springs, is capped with a holder/washer and the holder/washer is held on with a keeper. The keeper is actually two wedge shaped semi circles that catch the ringed grooves in the stem and then jam in the holder/washer. At right is a picture of the parts of the valve and spring assembly.

through the springs, is capped with a holder/washer and the holder/washer is held on with a keeper. The keeper is actually two wedge shaped semi circles that catch the ringed grooves in the stem and then jam in the holder/washer. At right is a picture of the parts of the valve and spring assembly.The valve compressor takes the pressure off the keepers and allows the washer/holder to be pushed down so the keepers can be removed. If removing the valves from an in place engine, the valve must be held up to allow the washer/holder to be pushed down and expose the keepers. If the valve is not held up, compressing the spring just lets the valve open. Two methods can keep the valve up - compressed air into the cylinder through the spark plug hole or a length of thin line fed into the spark plug hole and rotation of the engine to bring the piston up smashing the rope into the head, filling the cylinder and preventing the valve from opening. On a disassembled engine, you can hold the valve closed or put a roll of electrical tape between the bench and the valve. Once the valve spring is compressed, a little tap on the compressor and spinning the whole deal back and forth may be necessary to unstick the keepers from the washer/holder. Here is a picture of the compressor on the valve spring on the removed head and a close up that shows, a bit blurred, the keeper popping above the washer/holder.

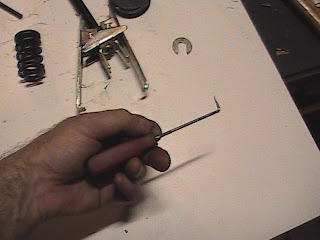

The inner and outer spring create a bit of a problem. The jaws of this compressor only reach the outer spring so there is still some pressure on the washer/holder but not so much that it cannot be overcome with a little hand pressure. It does create a three hand challenge which is made easier with a pick like this to pop the keepers out. Be careful because the keepers are small and they will fly.

I used a washer cut into a "U" to extend the reach of the jaws to grab the inner and outer springs. It did help, but there was still some spring pressure left. Here is a picture of the washer that hopefully shows how it should work. A little larger washer would have worked better.

With a little patience and the right tool, you can free the valve from the springs without damaging anything.

Next I will remove the broken spring from the engine that is in the vanagon and replace it with one of the spares.

Fascinatingly composed,Totally in wonder of the article.

ReplyDeletebest-spring-compressors