Two years ago on a whim I bought a 1985 VW Vanagon Weekender from a guy who was living in it up the street. He was a carpenter who was being hounded by the IRS. I doubt if he had ever made more than enough to libe on but he was apparently public enemy number one at the IRS office for never filing tax returns. I did not feel particularly happy about the situation he was put in, but he wanted to sell the van and I gave him his asking price, started the van and drove home two blocks, with the emergency brake on.

The first thing I did was drive around the neighborhhod looking for neighbors to freak out. I am a 45 year old trial lawyer. I am married to a wonderful and amazing woman and we have two children who are sixteen and thirteen. We live in a nice suburb about halfway between Annapolis and Baltimore. From all appearances, we are standard suburban family. Yes my wife is an artist and a designer and we do have creative non-conventional side. We are progressive liberal, but we live amongst and like many people who are country club/republican/private school/vacation in the islands/golf and tennis/I got mine/personal responsibility/former yuppie now suburban types.

As I am driving around the neighborhood with The Dead, Neil Young, Allman Brothers, Little Feat, Seldom Scene, John Prine, Buffalo Springfield and LA Dub Allstars playing, I am getting some looks from the neighbors. I am also getting some peace signs and "power to the people" salutes. Now the van is a good 13 years after the end of that era, but it still has the cache. It is freedom and empowerment. It is freedom because you can camp in it. It is empowerment because, as I have been learning, you can fix it,make it work, rebuild the engine, replace the clutch, do the brakes, grease the bearings, repack the CV joints and figure out all the wiring.

That is power.

Also as I was driving around on those first days of ownership, I was overheating the engine. There was a little "H" pipe that the previous owner (PO) had fixes with JB Weld. It leaked out the coolant. A little red light was blinking but I did not notice or care. Well when I figured that out I went on line looking for the part and found a wonderful place called The Samba. With the help of that forum, I had the knowledge to replace the head gaskets. After that repair, we were able to take the camper to Virginia Beach and had a fantastic time cruising in Sugar. On the way back, coming up I-95 and trying to keep up with traffic, the little engine just got too hot, the oil too thin and a connecting rod shot through the engine case. We rented a car carrier, borrowed a truck from some fantastic people in Fredericksburg and brought Sugar home. I found an engine on eBay, bought it and rebuilt it. Thats right, a lawyer took an engine completely apart, put it back together, put it back in the van and drove around under its own power. It worked for a little and more problems developed, but the point is, I built an engine that ran and powered a vehicle and it made me feel great.

In this era of the emasculated everyone, where no one can do anything, where nothing is repaired, where no one makes anything, this collection of German engineering, the people's car, can heal us. Sugar is a bread loaf looking brown brick of a vehicle that flips a big patriotic, can do, resourceful and independent bird to The Man.

I want to help others assert that independence.

I am no expert, but what I will do is carefully disassemble and catalogue the parts of a WATERBOXER engine for you. That and the technical expertise of the brothers and sisters on The Samba are all you need. So go find that 1983 to 1990 Vanagon and get empowered.

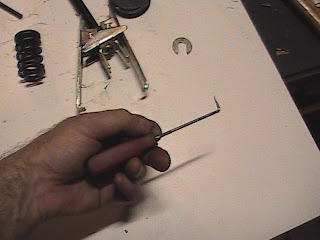

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs

The valve is held closed by the pressure of the springs. The flare part of the valve seals against the underside of the head and closed off the piston cylinder creating compression. I had no compression in cylinder three because of the broken spring. On the waterboxer, there are actually two springs, a thick outer and a thinner inner spring. The stem of the valve runs